The Complete Guide to Compostable Packaging

What Does it Mean to be Compostable?

Elk Packaging: Committed to Deep Green Solutions

Choosing Sustainability

Regulatory Changes

Are there Benefits to Packaging with Compostable Materials?

Packaging with Compostable materials can help people and the environment, while also helping businesses meet sustainability goals. Consumers increasingly expect the most sustainable option for packaging, especially in crowded categories. This leadership opportunity is a meaningful and exciting way to spotlight your brand's real dedication to actual change.

Improved Environmental Impact

Compostable materials help reduce the need for landfills by turning food waste into soil, which benefits the environment.

Less Pollution

Compostable Packaging has a smaller carbon footprint than regular plastics, resulting in fewer greenhouse gas emissions.

Consumer Appeal

Compostable Packaging is no longer just a feel-good option for consumers. Eco-friendly packaging is essential for younger consumers who prioritize the environment when shopping.

The Law of Packaging Specifications

Many states, including California, Maine, Minnesota, Oregon, and Colorado, have passed laws requiring single-use packaging to be Certified Compostable.

How is Compostable Packaging Produced?

Compostable Packaging companies create non-toxic materials from plant-based polymers, cornstarch, or cellulose. We choose these raw materials because they decompose naturally and enrich the soil without leaving harmful residues.

The raw materials then go through a transformation process. For example, cornstarch turns into polylactic acid (PLA), a common Compostable bioplastic.

Once the Compostable material is ready, manufacturers shape it into various forms of packaging. This includes biodegradable films, wrappers, adhesives, inks, and coatings, which are all Compostable.

The production of Compostable Packaging often embraces sustainable practices. Manufacturers may use renewable energy sources and minimize waste, further enhancing the packaging’s environmental benefits.

Several types of materials make up Compostable Packaging:

Plant-Based Plastics (PLA):

Derived from renewable resources like corn starch, these materials offer a clear, sturdy alternative to traditional plastics

Bagasse:

Molded Fiber:

Kraft Paper:

This natural, unbleached paper is perfect for wrapping, bags, and boxes, making it an environmentally friendly choice.

Made Close to Home

We produce our Compostable Packaging in North America, ensuring a short and efficient supply chain.

Experience Gets the Job Done

Our 15+ years of sustainability experience puts our technical team ahead of the pack in execution and innovation. With each project we commit to learning and evolving; it's our favorite part of the process.

How is the Packaging Material Composted?

Compostable Packaging breaks down in industrial composting facilities or in-home composting systems. Independent testers verify that Certified Compostable Packaging breaks down to the ASTM D6400 Compostable standard. This means the materials will disintegrate, bio-degrade, and pass eco-toxicity and heavy metal testing.

Here's a closer look at the breakdown process:

Microbial Activity:

Heat Production:

Moisture Levels:

Time Factor:

The time it takes for Compostable Packaging to break down can vary. Under industrial conditions, it can take as little as a few weeks. A certified Compostable product will break down within 180 days into pieces 2mm or less.

What Type of Packaging is Available in Compostable Materials?

Compostable Packaging is a great choice for many brands and industries. We've created Compostable coffee bags, Compostable labels, Compostable mailers, Compostable bakery packaging, Compostable clothing packaging, and more for our customers. New advances mean Compostable Packaging can be clear and show off the product inside.

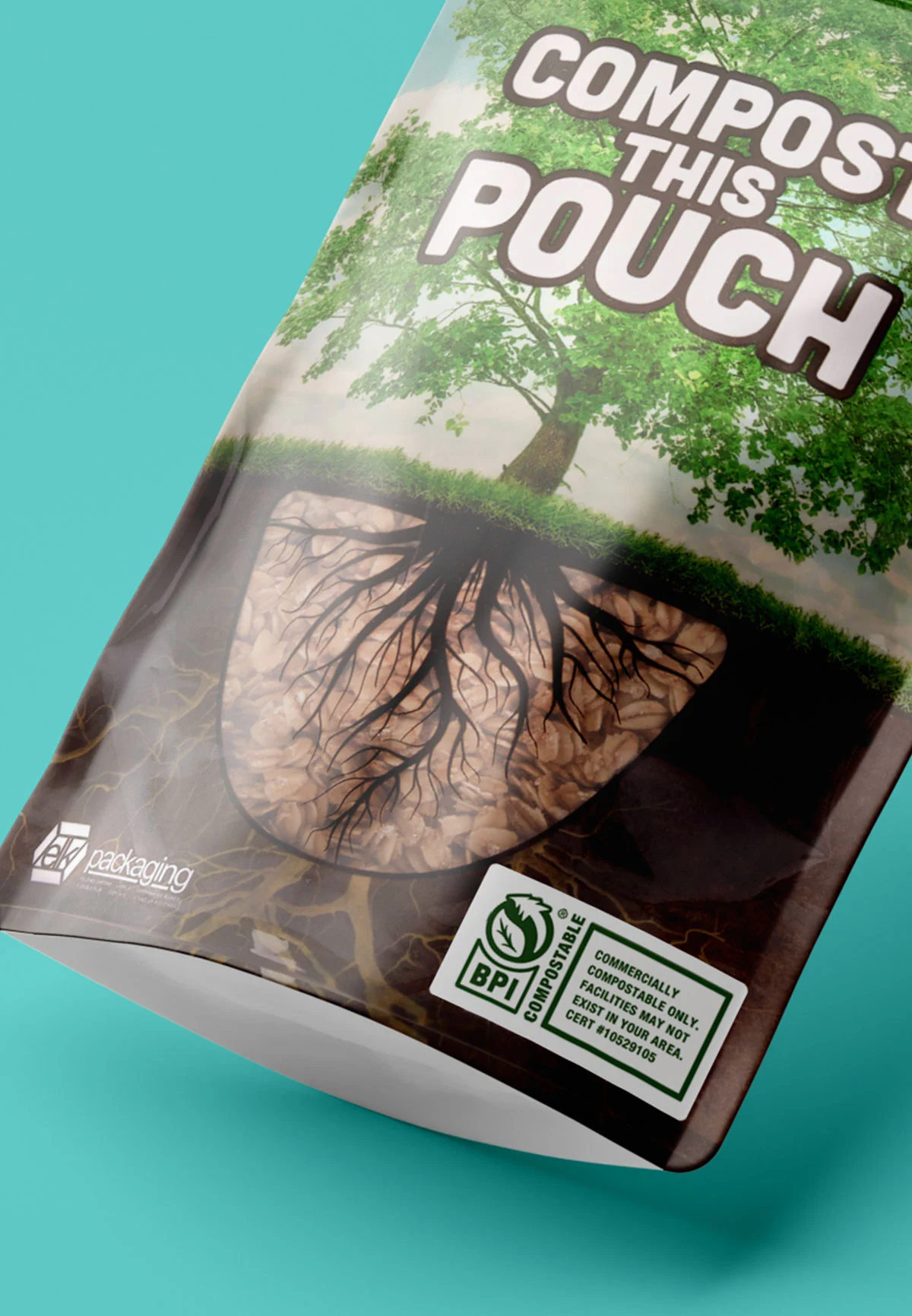

Things Your Brand Should Know About BPI Certifications & Legal Requirements for Compostable Packaging

Understanding BPI certifications and legal requirements is vital for your brand’s credibility and compliance. The Biodegradable Products Institute (BPI) certification ensures that packaging is Compostable in commercial composting facilities, adhering to industry standards.

Achieving BPI Certification

To receive BPI certification, your packaging material must completely break down in a composting environment. It should break down safely and quickly without leaving any harmful residue.The Legal Aspects of Compostable Packaging

Depending on the industry and product, brands follow specific guidelines when choosing packaging. Compostable Packaging must meet specific standards, such as ASTM D6400 or EN 13432. Certified and legally compliant Compostable Packaging will not only strengthen your brand’s reputation but also align with environmental responsibility goals.

How to Start a Sustainable Packaging Project

Maybe you're an established brand looking to transition from legacy films to a Compostable Packaging product. Or perhaps you represent a new brand looking to launch for the first time. No matter how long you've been in the business, our role is to guide the process every step of the way.

Determine Product Needs

Complete Material Selection

Launch Time

Packaging Formats

Gusseted Stand-Up Pouch, 2 or 3 Side Seal, Wrappers/Rollstock

Available Gauges

0.8 to 3.2 mil

OTR Film Barrier = 0.50

MVTR Film Barrier= 0.08

Finishing Options

Matte Coating, Spot Gloss, Window, with Zip-locks in Development

Appropriate Products

Single Serve Items, Tea, Snacks, Energy Bars, Chocolate, Frozen Foods

Compliance

SB 54 is a landmark packaging law that requires 100% of packaging in the state of California to be recyclable or compostable by 2032. This means a 25% cut in plastic packaging and 65% of all single-use plastic packaging must be recycled.

Packaging Awards

Elk Packaging has achieved significant recognition in the field of packaging innovation, as evidenced by our multiple awards and accolades.

Contact us for Sustainable & Standard Packaging Solutions